Food processing building design

worker is after all a better worker. Large window openings covered with a sandwich of metal mesh

and nylon mosquito mesh are a good way of allowing air to get to a building especially if the

direction of prevailing winds can be utilised.

As hot air rises, high level ventilation (with net covers) between the top of the walls and the roof will

increase air flows. If affordable, electric fans fitted on the ceilings are recommended.

General layout

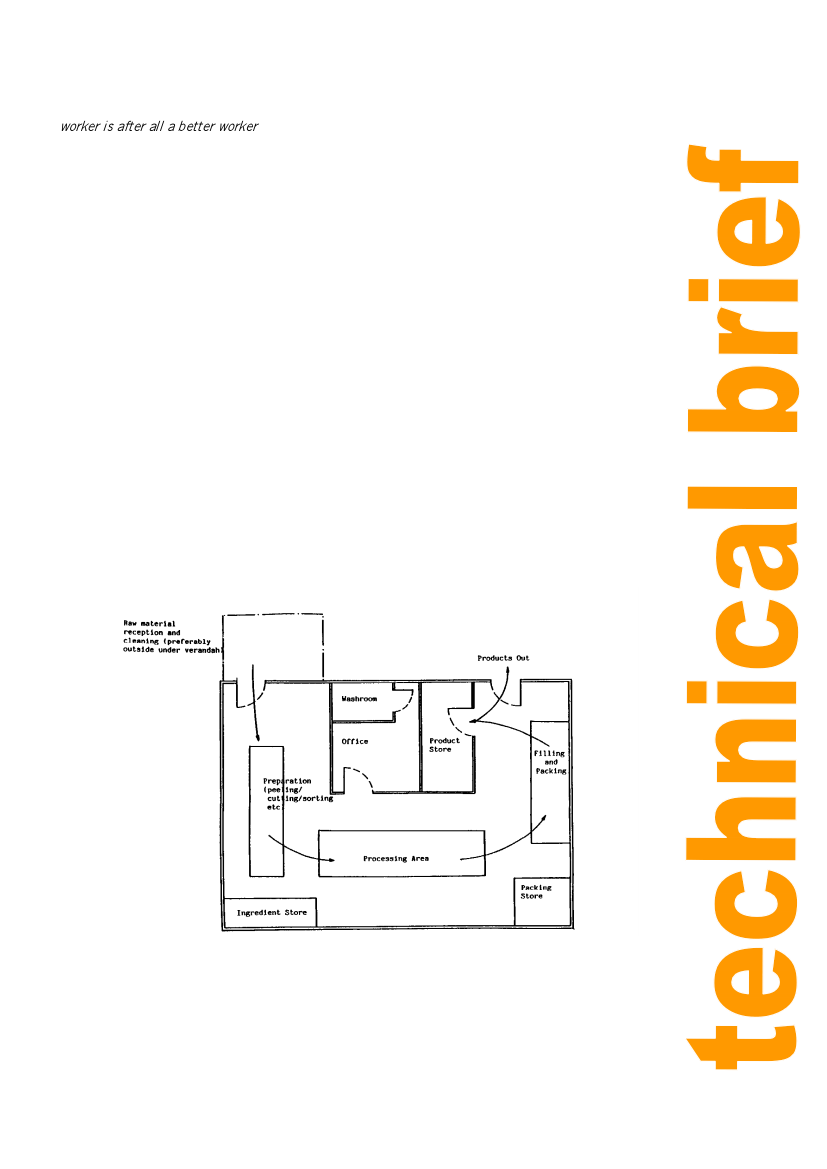

The various operations being used in a plant, need, within reason, to be kept separate. Bottle

washing for example, is best done outside to avoid any glass splinters from the inevitable

accidents getting mixed up with the production process. Perishable raw materials should be

kept separately as should non-perishable raw materials. Packaging again should be separately

stored and there should be some form of divided office area. Toilets, if at all possible, must be

housed in a separate building. If they have to be placed in the main building, two doors should

exist between the WC and the production area. For good hygiene, workers must have access to

at least hand washing facilities with soap and clean towels. A shower cannot be recommended

too highly as this allows the workers to wash thoroughly at the beginning of the day.

Figure 1 shows a typical layout of a food processing room, showing how raw materials move

through the process (and through the room) without paths crossing. This helps prevent

contamination of finished products by incoming, often dirty, raw materials and clearly identifies

areas of the room where special attention to hygiene is necessary.

Figure 1: A food processing room

2